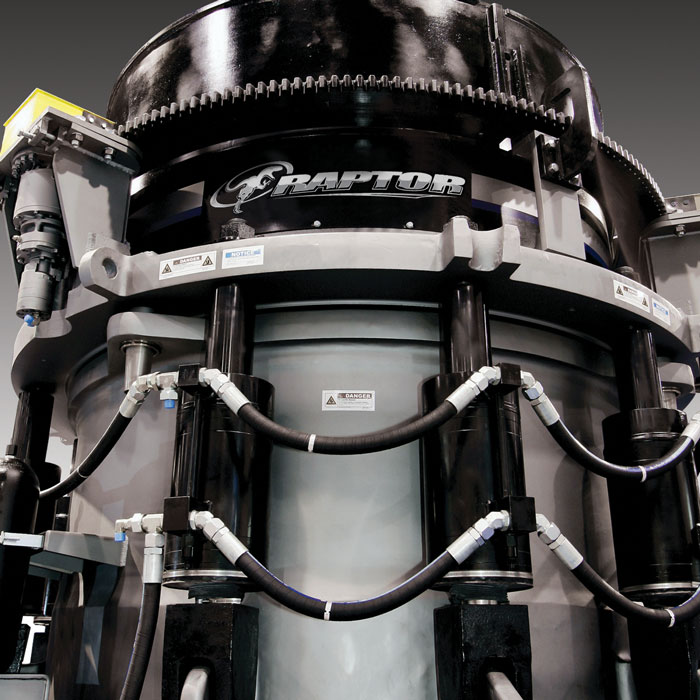

FLSmidth Raptor 500 hp and Over Cone Crushers

Raptor® High-Performance Cone Crushers offer cost-effective solutions for medium- to high-tonnage aggregate and mining operations. Available in sizes ranging from 500 hp to 2000 hp these rugged, durable machines offer many advancements in design and innovation.

More Crushing Force

Raptor® High-Performance Cone Crushers offer more crushing force with high pivot point and large crushing stroke for better end product shape and high production of salable material. Raptor Cone Crushers are the result of extensive research with the operators in the field. Our new design offers maximum productivity and maintenance benefits:

Alloyed cast steel three-arm Main Fame; one oversized arm used for the Countershaft cartridge

High-grade ASTM A148 cast steel on major components are weld repairable

Built-up Head Seat area with wear indicator groove provides quicker repairs and reduced cost

Head Skirt lends additional counterweight wear protection

Counterclockwise Crusher Rotation opens bowl during a tramp event, protecting the crusher

Hydraulic Tramp Release Cylinders install rod-end down, reducing rod scoring/seal damage and dust contamination

Fewer Tramp Release Accumulators ease pre-charge pressure check and minimize maintenance

Built-in Relieve Valve provides secondary protection if pre-charged pressure is lost

Lubrication System’s submersible pump is less complicated and avoids leaks

Superior bronze components resist friction and fatigue

Fail-Safe hydraulic protection system minimizes structural overloads if an accumulator bladder should fail – protecting hydraulics and crusher

Automated features offer additional benefits:

Advanced overload sensing technology with simple alarm or automated correction

Feed control

Closed-Side Setting (CSS) adjustments

Monitoring of all critical lubrication and hydraulic parameters

Fail-safe hydraulics via internal relief valve within dual-acting tramp release cylinders

Mechanical overload protection in the event of an accumulator bladder failure

Counterclockwise rotation to protect machine from excessive adjustment ring movement and in the event of ring gear brake failure

Automated “Integrity of Position” to maintain constant CSS and position

Multiple hydraulic cylinders for instantaneous return to CSS after a tramp event

Rotating Bowl that adjusts for differential wear from segregated feed conditions

Size Reduction Versatility

The Raptor® High-Performance Cone Crushers are designed to operate and remain mechanically sound at lower eccentric speeds. The crusher speed can be selected to:

Maximize throughput

Target ideal size reduction

Produce desired product shape

Increase product yield

The versatile 500 hp XL500 Cone provides excellent secondary crushing capabilities, producing more material of desired cubicity and gradation than its competitors. It is a semi-portable unit offering higher capacity with multi-site setup flexibility.

The XL600 Cone can be installed to replace cone crushers with a 59-inch (1.5 m) head diameter or larger without major modifications to foundations or feed arrangements, allowing an increase in production capacity without major plant modifications.

The XL900 Cone can be installed to replace cone crushers with a 59-inch (1.5 m) head diameter or larger without major modifications to foundations or feed arrangements allowing for increasing production capacity without major plant renovations.

The XL1100 Cone can draw up to 1,200 hp and delivers production capabilities of up to 2,240 TPH (2,000 tonnes) at a 1-1/3-inch (35 mm) closed-side setting. The unit handles feed size up to 24 inches (620 mm)

The XL2000 Cone doubles the capacity of the XL1100 cone. This direct drive 2000 hp variable-speed machine has a significant eccentric throw and high-pivot point crushing action delivering production capabilities of up to 3,500 TPH (3,175 tonnes).

Mining

The XL900, XL1100 and XL2000 Raptor® Cone Crushers are perfect for secondary, tertiary and quaternary mining applications.

With its higher pivot point and larger crushing stroke, the XL900 Cone delivers more crushing than other competitive models of the same size:

Perfect for mines needing a large secondary cone crusher

Delivers almost 1,400 TPH (1,270 tonnes).

Can be installed to replace cone crushers with a 59-inch (1.5 m) head diameter or larger without major modifications to foundations or feed arrangements

Designed to operate and remain mechanically sound at a wide range of eccentric speeds.

Fail-safe hydraulics

Integral Countershaft Assembly

Enclosed Counterweight Assembly with replaceable non-contacting T/U Seal arrangement

Ductile Iron Eccentric

The XL1100 Cone breaks productivity barriers while its integrated Countershaft in the three-arm Main Frame delivers unmatched durability:

Draws up to 1200 hp

Maximum throughput of up to 2,240 TPH (2,000 tonnes)

Can be installed on the foundation of a smaller head machine

Fail-safe hydraulics

Integral Countershaft Assembly

Enclosed Counterweight Assembly with replaceable non-contacting T/U Seal arrangement

Ductile Iron Eccentric

The XL2000 Raptor Cone Crusher doubles the capacity of the previously largest cone crusher and offers new industry leading features:

NEW Double-acting Tramp Release and Clearing Cylinders (patent pending)

NEW easy access to critical load carrying Bearings

Significant Eccentric throw and high-pivot point crushing action

Direct drive as 2000 hp with variable speed option

Delivers up to 3,500 TPH (3,175 tonnes).

Fail-safe hydraulics

Integral Countershaft Assembly

Enclosed Counterweight Assembly with replaceable non-contacting T/U Seal arrangement

Ductile Iron Eccentric

Spiral Bevel Gearing

Aggregate

The XL500, XL600, XL1100 and XL2000 Raptor® Cone Crushers are perfect for secondary, tertiary and quaternary aggregate applications.

The Raptor XL500 Cone Crusher has a maximum diameter of 148 inches (3.75 m) and weight of 106,500 lbs (48,300 kg), allowing flexibility for multi-site crushing opportunities:

Rigid four-arm frame and integral countershaft mounted inside one of the four arms

Enclosed counterweight assembly with replaceable non-contacting dust seals

Advanced eccentric of high-strength, ductile iron casting

Spiral-bevel gearing to transmit loads without shock or sudden impact on the teeth

The XL600 Cone Crusher is a high-performing, cost-effective solution for medium-to high-tonnage aggregate and mining operations:

Designed to operate and remain mechanically sound at lower eccentric speeds

Crusher speed can be selected to maximize throughput, size reduction, product shape and product yield

High pivot point and large crushing stroke

Can be installed to replace cone crushers with a 59-inch (1.5 m) head diameter or larger without major modifications

The XL900 Cone Crusher delivers more crushing action from the first nip at the feed opening and through the chamber until the material exits the parallel zone:

Higher pivot point and larger crushing stroke

Maximum throughput capacity of almost 1,400 TPH (1,270 tonnes)

Handles feed size up to 14.57 inches (313 mm) allowing a reduction ratio of up to 6:4

Active feed opening provides a desirable cubical product shape

Large 71-inch (1.8 m) crushing head, but can replace cone crushers with a 59-inch (1.5 m) head diameter or larger without major modifications

Designed to operate and remain mechanically sound at a wide range of eccentric speeds Eccentric speed can be selected to maximize throughput, size reduction, product shape or product yield

With its integrated Countershaft in the three-arm mainframe, the XL1100 Cone breaks productivity barriers and delivers unmatched durability:

Draws up to 1200 hp

Can be installed on the foundation of a smaller head machine, saving plant renovation costs

Heavy-duty hydraulic design with fewer required accumulators

Advanced eccentric is nodular iron casting of high-strength

Spiral-bevel gear for durability and reliability while minimizing gear noise

Available with Shorthead or Standard Bowl configurations

The XL2000 Cone doubles the capacity of the previously largest cone crusher and offers industry leading features:

Fail-safe hydraulics

Integral Countershaft Assembly

Enclosed Counterweight Assembly with replaceable non-contacting T/U Seal arrangement

Ductile Iron Eccentric

Spiral Bevel Gearing

NEW Double-acting Tramp Release and Clearing Cylinders (patent pending)

NEW easy access to critical load carrying Bearings

Significant Eccentric throw and high-pivot point crushing action

Direct drive as 2000 hp with variable speed option

Automation

FLSmidth’s Raptor® automated controls improve cone crushing performance by ensuring the crusher operates at optimal efficiency:

Available in five packages for all Raptor Cone Crusher models

Self-contained controllers provide full-time monitoring and automated controls

FLSmidth’s Raptor Basic Automation System

Simple interlocks, pushbuttons and indicators monitor crusher’s performance and settings

FLSmidth’s Raptor Automated Interlock Automation System

Simple programmable logic controller (PLC) establishes, calibrates and monitors crusher settings.

One-button push start allows system to monitor lubrication and hydraulic pressures, temperature and vibration

Features audio and visual indicator alarms

FLSmidth’s Raptor Full Automation System

Combines PLC controls with Windows®-based Rockwell FactoryTalk View® SE interactive software

Remotely controls cone crusher.

Contains same basic controls, indicators and push start as Automated Interlock Automation System

Provides data collection for trending, wear part replacement, diagnostics and troubleshooting

FLSmidth’s Raptor Custom Design Automation System

Custom-designed automation systems provide complete automation integration within an operation

Modify and incorporate any standard Raptor Automation feature to specific criteria and systems within plant layout.

Custom Automation Systems can accommodate any stationary, portable or mobile plant system/design

Remote Liner Calibration System

Affordable option to remotely manage a crusher’s CSS (closed-side setting) adjustment

Eliminates safety and downtime associated with manual “slugging” for desired CSS

Allows for frequent adjustments

Improves crusher performance and product quality

Available for Raptor cones and other crusher models with ring bowl adjustment

Package Lube & HPU

The Package Lube System is designed and sized to provide the necessary supply of clean and cooled lubrication oil and is available in an air-cooled or water-cooled package, depending on requirement. Both systems feature a skid-mounted reservoir with one or two lube oil pump and motor assemblies and include:

Package Lube System 80gal

Package Lube System 80 gal

Full flow oil filter with integral pressure relief

Water/oil heat exchanger (for water-cooled system)

Replaceable filter element and pressure switches to indicate filter element conditions

Reservoir with oil level sensor, temperature sensor and a thermowell mounted oil heater

Submerged oil pump attached to a vertically positioned electric drive motor

Main system relief valve

Crusher relief valve

The Hydraulic Power Unit is designed and sized to provide the necessary oil flow and pressures to operate bowl clamping, bowl adjustment, crusher cavity clearing and the tramp release systems. The power unit can be controlled locally at the push button panel or at the Automated Control System (ACS) touch screen. The Hydraulic power unit includes:

Hydraulic Power Unit

Hydraulic Power Unit (HPU)

Cabinet with an integral oil tank and replaceable breather

Vertically mounted electric motor

Submerged hydraulic pump

Solenoid valves

Oil filter

Remote-mounted pushbutton control panel