KINGSON

KINGSON’S MISSION AND PHILOSOPHY

Mewar Hitech is committed to excellence in quality of its equipment and takes pride in on dedication to customers and associates. We are committed to provide the best quality crushers, screens & customized size reduction equipment and satisfactory after sales services at competitive prices. We timely deliver out highly quality equipment to meet customer requirement. We provide professional advice to our customer, find innovative solutions to their specific requirements and treat them us our business partners, out professional approach, after sales service and timely supply of spare parts at most reasonable prices make us ideal choice as business partners.

We have wide range of Industrial Products for crushing, screening & other customized size reduction equipment such as Bucket Elevators.

Mewar Hitech has strong teams of highly qualified and experience engineers/technicians/draftsmen & professional commercial staff, who can assist in pre-selection, timely supply of high quality equipment at competitive prices, erection & commission there as well as provide after sales assistance and required spares. Our staff works is a cohesive & collaborative manner which has resulted in our rapid growth and made us most favored supplier of crushing, screening & customized equipment. We have qualified and experienced workmen, who are committed to our business philosophy.

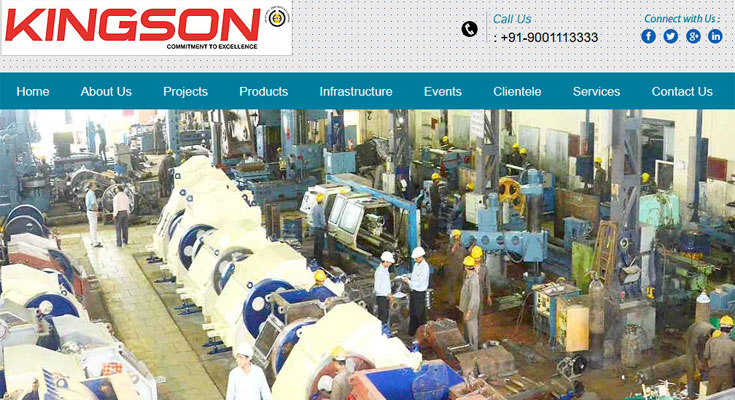

We have the following equipment and all most all jobs are carried out in-house without dependence on out sourcing, which results in timely supply of quality equipment. We are work closely with our customers and with our innovative and R&D based approach provide solutions to our customers. This has resulted in a host of satisfied customers, who have given us repeat orders:

1. Horizontal boring machine for crusher body machining, which can bore all required openings and ensure parallel & centre distances, accurately.

2. Table type Horizontal Boring Machine, which can achieve Pitman parallelity and accuracy.

3. CNC Plasma cutting, which can achieve accurate and fast cutting, as per drawing Also, it can ensure maintain once of details as per design/drawing.

4. CNC Lathe Machine, for large quantity with accurate machining.

5. Hobbing Machine, this can produce worm reduction Gear on in-house basis.

6. Shot Blasting Machine, which can achieve excellent surface preparation at a fast rate.

7. Annealing Furnace, this can handle finished crusher body for stress relieving of cast and fabricated parts.

8. Induction Furnaces, to cast MS and Alloy steel parts to ensure its specific composition.

Our design / drawing and R&D centre, which ensure timely supply of good quality equipment, it also helps find innovative ideas and solutions to various technical issues.

QUALITY POLICY

Mewar hitech pays special attention to quality aspect of materials that are used for manufacture of its equipment. All in coming materials (including castings done in-house) are tested before these are used in manufacture of equipment. Our qualified and experienced engineers, technicians and workmen have dedicated approach. They are given in-house and external trainings and our approach is of ‘zero defect’. Our equipment is fully tested before dispatch and performance tests are carried out before dispatch.

Mewar Hitech keeps inventory of consumables and spares and these are supplied at short notice and at reasonable prices.

Our CMD, Mr. CS Rathore personally monitors quality control of equipment manufactured by us.

As an assurance of our quality, we are accredited with 1S0:9001:2008 for design, manufacture & supply of crushers, screens and other customized size reduction equipment.

Why Kingson ?

1 . The company is accredited with ISO 9001:2008 quality system certification for design, manufacture and supply of crushers, screens and size reduction equipment.

2. In-house facilities including CNC Measure Cutting machine, CNC Lathe machines, shot blasting machines, Horizontal Boring Machines, Vertical Lathe Machines, Shapers, Planers, Sharing and breaking machines, lathe machines, Heat treatment furnaces, etc. This ensures good quality and timely delivery of equipment as there is no dependency on out- sourcing.

3. Qualified and experienced workforce and staff for accurate work.

4. Regularly evaluated by CRISIL and constant high rating.

5. Excellent test facilities at the factory Raw materials, in process and product tests are carried out on each individual equipment being manufactured. Also, state-of-the-art R&D facility ensures high quality equipment supply.

6. At any Indian site assistance is ensured within 48 hrs .

7. Timely availability of spares from our Branch offices and Dealers in different areas of India and abroad.

8. Projects on Turnkey basis, Installation Facilities ( Erection, Commissioning & Civil Team )

9. Highly competitive prices for high quality equipment.

10. Wide and Customized Product range.