AGG-PRO

Aggregate Processing and Recycling (AGG-PRO) has an accumulation of over thirty years of experience in the construction industry. This experience has been gained from design, manufacture, sales and servicing of all types of construction equipment, specializing in crushing and screening equipment. With a huge amount of in-depth experience with most types of manufacturer’s machinery and wear parts, APR believe that the GIPO, Magotteaux and McCloskey range of machines are of the highest quality, highest performance and best overall value for money that is available GLOBALLY today.

TOTAL COMMITMENT TO AFTER SALES & SERVICE

APR believe that over recent years many of the previously well respected manufacturers have all fell into the trap of mass production resulting in lower cost, lower quality products with very poor after sales service. APR believe that this may suit many operating companies with short term plans, however when a company has greater long term ambition and foresight the benefits can be far greater by selecting machinery of this type. APR is committed to provide machinery that is tailored to suit, or if necessary customized to suit the best needs of the operation. APR believe that an offer of total commitment to the after sales and service dedication is the most important aspect that must always be paramount with any respected machinery supplier.

OUR SERVICE

At APR we employ all our own fully trained service staff, APR has its own 28,000 sq ft workshops in the UK complete with all the necessary equipment to service, or if necessary manufacture new parts on site. We also operate extensive spares and service facilities in the Middle East and West Africa and we believe that having full control of staff and facilities allows us to operate at maximum efficiency to offer you the client – TOTAL SERVICE.

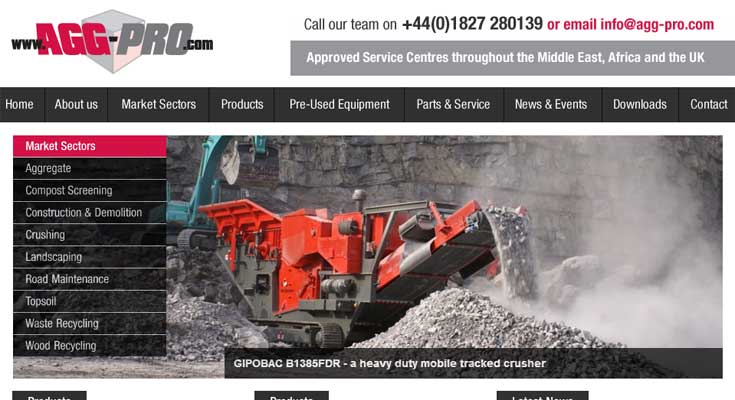

GIPO Located in Seedorf, Switzerland GIPO have always set the standard in the area of processing systems. The first GIPO machine was developed around 25 years ago; today as a Swiss pioneer in mobile crushing and screening, their engineers make a vital contribution to the on-going development of components and machine types. One of their latest developments the combination of the crusher and the screen has introduced distinct space, environmental and cost advantages. GIPO plants are being operated extensively throughout the world. They are distinguished by top quality componentry combined with diesel-hydraulic actuation and offer proven longevity. New technical innovations are continually incorporated.

MCCLOSKEY

Based in N.Ireland McCloskey equipment offers the complete solution for Crushing, Screening & Recycling Equipment.

Trommels

Since 1986, McCloskey has been a pioneer in trommel design and innovation. With a keen focus on listening to customers’ needs, McCloskey International developed and patented the remote control 180 Degree Radial Stockpiling Conveyor with variable discharge height for maximum stockpiling flexibility. This development, along with other pioneering features such as the solid rubber wheel drive system, has made McCloskey International the number one trommel manufacturer in North America. With proven performance for material throughput, quality components and customer focused features, McCloskey International continues to be the world leader in trommel design and manufacturing.

Vibrating Screeners

McCloskey vibrating screeners are all built around the industry leading High Energy Screenbox which maximizes vibratory power with a longer stroke and heavy-duty eccentrics, applying more energy to material in the screenbox to accelerate throughput. A range of screens is available to give customers high output and durability in the harshest of conditions. With the Heavy Duty R-range, the High Energy S-range for finer applications, and the highly versatile Kompaq and Sizers, McCloskey flat-decks can handle any application from on-site construction and demolition, to large aggregates and quarry applications.

Conveying Systems

McCloskey stackers have a unique and patented counterweight system and are designed to be the most practical solution on the market. With features such as the pivoting discharge conveyor, McCloskey stackers can swivel through a radius of 180º, ensuring greater stockpile capacity without moving the installation, equalling less downtime for operators. A full line of tracked stackers allows operators to easily and efficiently move the stackers into position.

Crushers

A full line of mobile crushing plants, including jaw, cone, horizontal shaft impact, and vertical shaft impact crushers. McCloskey’s extensive range of equipment suits a range of industries that include topsoil, compost, mulch, sand and gravel, landscaping, road building, golf course construction and maintenance, construction and demolition, waste management and aggregates. With such a wide selection of equipment, you can choose from a variety of options to fit your specific application needs.