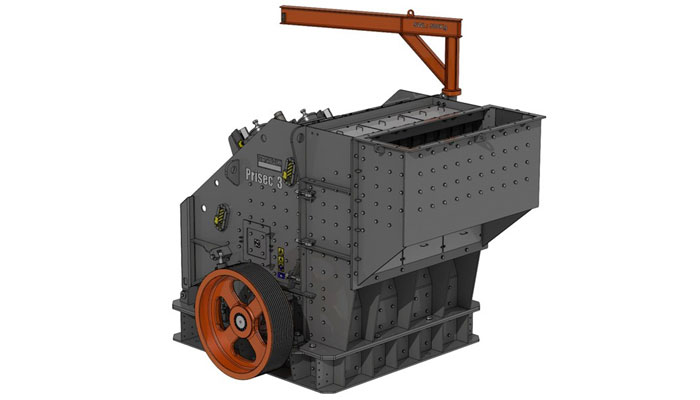

SANDVIK Stationary HSI Impact crushers

Two configurations in one

Our new range of Prisec™ crushers has been developed in response to customer demands, further building on the rock-solid foundation of the P&S series it replaces.

All crushers in the range can be configured to operate in application areas such as quarrying and recycling, in either primary or secondary crushing mode. Our patented design gives you amazing adaptability, ensuring you keep pace with ever-changing production requirements.

Great reduction ratios – greatly reduced maintenance costs

Our new revolutionary crushing chamber delivers greater reduction ratios than were previously obtainable. Two uniquely designed extra heavy duty curtains give the throughput and reduction ratios that our competitors require three curtains to produce. This means fewer wear parts and reduced maintenance.

Both curtains are infinitely adjustable via our patented hydraulic adjustment/braking system, using the standard supply electric hydraulic power pack.

No more crusher blockage – what would it mean for you?

It’s a bit historical problem, especially when operating in a primary configuration. But our PrisecTM crusher eliminates the blockage, as well as the associated downtime and health and safety risks.

Our HSI crushers are for the primary and secondary crushing of non-abrasive rocks (<0.3 Ai Bonds abrasion index), in aggregate production. However, they are also used extensively in the recycling industry, crushing a variety of materials including re-enforced concrete.

Since their working principle encourages material to break along its natural cleavage planes, they produce excellent, stress-free, cubical-shape products.

They are of the open rotor type, with many advanced and user-friendly features.

Typical applications could be making a Type 1 aggregate 0–40 mm (0 –1 15/16″), or Railway Ballast 40 –70 mm (1 15/16″–2 ¾”), or recycling / crushing of re-enforced concrete and Asphalt. All together this means: Low capital outlay, low maintenance, fewer screens and conveyors, quick return on investment.

Features and benefits

Amazing reduction ratios

Energy efficient overload protection

Crusher blockage elimination

Hydraulic Curtain Adjustment and Frame Opening

Easy and safe maintenance

| Model | Weight kg /lbs |

Max. feed size mm /in |

Capacity tph |

|---|---|---|---|

| CI511 | 9160 / 20194 | 600 / 23,6 | < 150 |

| CI512 | 9160 / 20194 | 600 / 23,6 | < 200 |

| CI521 | 16000 / 35274 | 900 / 35,4 | 200 – 400 |

| CI522 | 16256 / 35838 | 350 / 13,8 | 150 – 250 |

| CI531 | 27750 / 61178 | 1000 / 39,4 | 400 – 700 |

| CI532 | 29650 / 65367 | 350 / 13,8 | 250 – 400 |