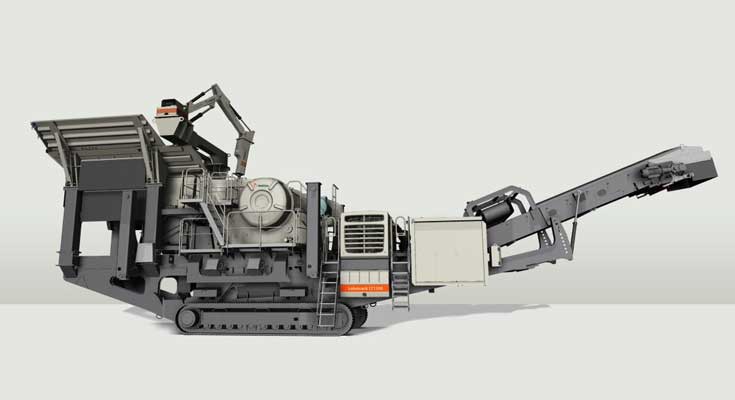

Lokotrack LT130E mobile jaw crushing plant

The new Lokotrack® LT130E™ mobile jaw crushing plant is the right choice for primary crushing in quarry operations. Its heavy duty design guarantees a reliable solution and high capacity even with the hardest of feed materials. The LT130E can operate electrically with external power source or by using on-board diesel generator when there’s no external power source available.

Features

The new Lokotrack® LT130E™ mobile jaw crushing plant is an extremely robust primary crusher built by using heavy-duty steel structures. The LT130E has been designed for higher capacity requirement and it also accepts larger feed material than its predecessor LT125™. During operation, the LT130E is electrically driven. To achieve the minimum operational cost, an external power source is recommended. In locations where this is not possible, an integrated CAT® C15 engine and 500 kVA generator power package ensure efficient operation.

Nordberg® C130™ jaw crusher on the Lokotrack LT130E takes capacity to a new level in large-scale quarry applications. A deeper 1 000 mm (40”) feed opening is able to handle coarser feed material and it greatly reduces the need for blasting. A small nip angle and excellent kinematics ensure aggressive crushing along the whole length of the crushing cavity in all rock conditions.

Metso made it easy to adapt Lokotrack LT130E for your existing process. You can just adjust height of the main conveyor hydraulically and start the process. An advanced Metso IC process control makes sure that the process runs smoothly and it also connects to the following Lokotrack crushing and screening plants wirelessly or by using interlocking cable. Excellent working space on platforms and easy access to all maintenance locations makes your daily routines much easier than before.

Benefits

Heavy duty design for the most demanding applications

Reduced need for blasting due to the bigger feed size

Economic operation by using external power source

High-performance generator to provide power for the LT130E and additional equipment such as a screen

Safe and easy setup and maintenance due to extensive platforms, advanced design and quick couplings

Optimized transportation

The Lokotrack LT130E can be optimized to move between different sites. All the electric and hydraulic connections have quick couplings for easy disassembly. Optimized lifting points and extensive platforms increase safety and enable you to move faster.

“Easy Split” feature makes your life much easier if you move regularly. Especially in contracting use you can operate without a crane and set up the plant within a matter of hours. The “Easy Split” utilizes hydraulic cylinders to lift the crusher and feeder above the body of the Lokotrack LT130E. After this the crusher and feeder can be moved on a standard trailer. Body of the LT130E can be driven to the trailer by using remote controller just like in a smaller Lokotrack mobile plants.

How it works

Material is fed on to a feeder by excavator or wheel loader. The robust feeder removes the fines and keeps crusher full. Fines can be guided to main conveyor or side conveyor. Output material size is controlled by crusher setting. The main conveyor transports the material into the next unit or a stockpile. Discharge high of the main conveyor can be hydraulically adjusted in the Lokotrack LT130E.