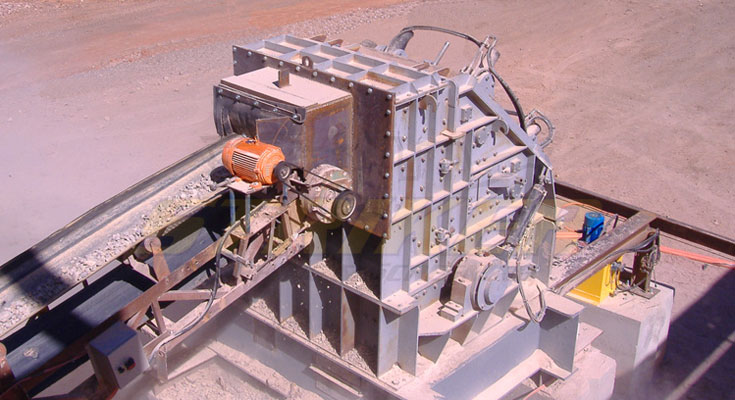

Striker 900HD series Impact Crushers

BARE IMPACTOR FEATURES (NOT TRACKED)

The SCE – HD series of Impactors are designed for primary or secondary crushing of highly abrasive materials, recycling materials and medium-low silica materials when large reductions are required. Highly abrasive materials include sandstone, gravel, granite, basalt, gold ores, refractory rejects, cement clinker and others. Recycling materials include asphalt, concrete, building rubble, bricks and others. Medium-low silica materials include limestone, dolomite, bauxite, shales, gypsum, clays, coal and others.

Extra Heavy Duty Rotor-SCE – HD Impact Crushers incorporate heavy, open disc style, four blow bar rotors as standard. Blow bar support beams are sized to ensure the SCE rotor has the highest moment of inertia available. This is important in absorbing the forces generated by the Impacting process and is a key factor in our success with achieving large reduction ratios. The rotor is supported by bearings mounted in massive solid housings manufactured from steel blocks with self-purging labyrinth seals.

Heavy Duty Blow Bars – The SCE – HD Series Impactor is equipped with 100 thick blow bars in 18% manganese iron offering the highest wear metal utilization factor available. The blow bar thickness can be increased to suit the crushing of highly abrasive materials. The service life of the blow bars is extended through a design that permits the bars to be lifted via the top as wear occurs or alternatively worn down and turned. Maintenance is safer and easier than in other designs.

Large Inlet Opening – Up to 500mm feed material can be handled in the extra heavy duty SCE – HD type Impactors. This ensures the large reduction ratio achieved by these machines is maximized.

Fully-hydraulic Impact Arms – Impact plates are cast blocks identical and interchangeable, thereby permitting optimum utilization. Gap settings between impact arm and rotor are adjusted hydraulicaly to allow the product size to be controlled. Hydraulic pressure on the impact arms is pre-set to resist the passage of uncrushed material through the impactor. If overloading, power failure, etc. causes material to exceed the pre-set pressure the impact arms retract in a controlled manner. Following completion of the retraction movement, the arm returns automatically to its pre-set gap position.

Wear Liners – Wear plates are generally cast from 28% chrome iron with a large proportion identical, thus interchangeable and turn-able.

Open Discharge – Large discharge opening allows for free discharge – no clogging – no capacity reduction.

High Serviceability & Access – The housing opens up hydraulically at the rear for maintenance and repair work. When the casing opens the blow bars are accessed in the vertical position. This enables the blow bars to be adjusted or replaced safer and easier than in other designs.

Every machine is constructed to handle a variety of crushing duties. We believe all customers should benefit from the reduction in operating costs these innovative Impact Crushers bring to the market. SCE – HD Impact Crushers include the best materials and the latest design features in all our machines.

http://miningpedia.xyz/striker/striker-900hd-series-impact-crushers.htmlhttp://miningpedia.xyz/wp-content/uploads/2015/12/striker-900hd-series-impact-crushers.jpghttp://miningpedia.xyz/wp-content/uploads/2015/12/striker-900hd-series-impact-crushers-150x150.jpgStrikerimpact crusher,STRIKER