SANDVIK Stationary roll crushers

Handling wet and sticky materials

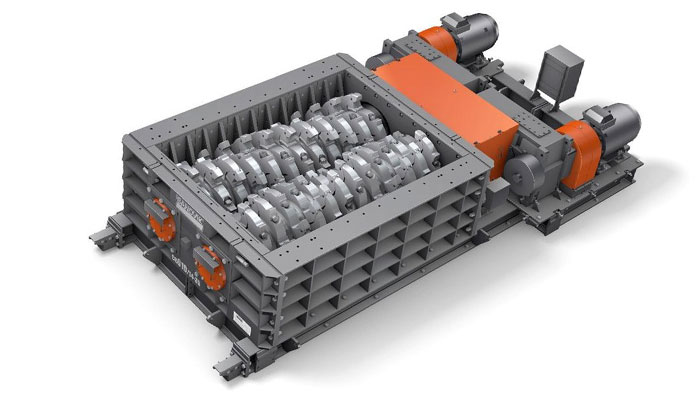

Our sizers are used in open-pit mining (ROM) for primary, secondary and tertiary crushing. The feed material is crushed either by counter-rotating rolls (CR610 center sizer) or between the rolls and the crushing plates by outwards rotating rolls (CR620 side sizer).

The inclined lateral parts, with integrated crushing combs, allow a product feed of large lumps. Size reduction is attained by shearing stress and pressure, generated by high torque at the crushing roll.

Our hybrids can handle wet and sticky materials, and are a great choice for primary and secondary crushing of soft and medium-hard materials. They can also be used in IPCC installations.

The CR610 is a highly efficient sizer. Designed with a large space between the crushing teeth, it generates a final product with a small content of fines. The distance between the crushing rolls can be adjusted to fine tune the product size and to compensate any wear. For increasing the crushing ratio, but also to get a more cubical product shape, the CR610 can be equipped with a breaker bar. The elastic mechanical coupling absorbs strong any shocks that may occur.

Features and benefits

Large teeth space

Adjustable crushing rolls gap

Can be equipped with a breaker bar

Elastic mechanical coupling

Highly wear resistant

Easily replaceable wear and spare parts

For efficient crushing at both crushing gaps of the side sizer, the CR620 is equipped with durable and wear resistant teeth, both on the crushing rolls and on the crushing combs. In addition, the crushing rolls have a composition of segments, which are easily replaced without having to exchange the complete roll. The staggered arrangement of the teeth also ensures efficient material feed and good product quality. Both rolls are driven individually by a motor, fluid coupling, gear and teeth coupling, which is connected to the rolls. The crushing rolls, the drive systems and the housing are arranged on a sturdy machine base frame.

| Model | Roll diameter mm / in |

Roll length mm /in |

Max. feed size mm /in |

|---|---|---|---|

| CR610 | 800-1400 / 31.5-55.1 | 1500-3500 / 59.1-137.8 | 1800 / 70.9 |

| CR620 | 700-900 / 27.6-35.4 | 1500-4000 / 59.0-157.5 | 300 / 11.8 |